FULL 360° DRYING

You wouldn’t think of running your recycling machine without an air dryer to keep the air/grit dry . . . NOW you have a cost-effective way to insure that every pound of wet grit you vacuum up is completely dry, ready to use without plug-ups when you restart blasting.

Wet grit . . . it costs you valuable time & money by reducing your productivity and increasing your cost per sq ft.

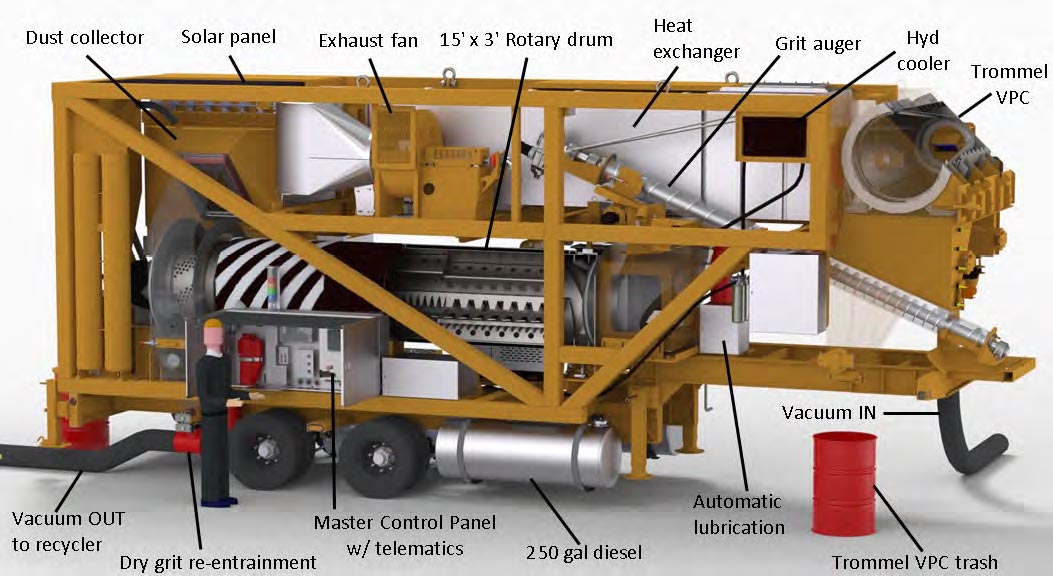

Rain "Insurance": now comes in the form of a new tool - a GD1K-T ROTO Grit Dryer™ machine that proactively provides a hedge against the costs of moisture. Best of all, with just 2-5 days of use each month, you could see a 100% ROI on the monthly rental rate.

Features

Benefits

FAQs

Because moisture is costing you a LOT of time/money that can be moved to your bottom line by using a ROTO Grit Dryer™ machine for proactive "rain insurance". In the process, you can gain a competitive advantage by reducing the financial risk associated with moisture damage to steel grit and reduced productivity from plug ups.

If your steel grit isn’t flowing smoothly through the metering valve without plugging, it is reducing your worker productivity, extending the length of your project and increasing your cost of abrasive blasting, hour by hour, week by week, month by month, year by year, square foot by square foot. It is also very expensive to replace and dispose of damaged steel grit.

No, as vacuuming speed is controlled by the weight of the dry or heavier wet grit. When you remove the moisture, you also remove weight, and the grit will vacuum as it normally does.

Whenever you know or detect moisture in the grit, you will benefit by drying it as soon as possible, preventing it from corroding/clumping on the ground or in your recycler.

Yes, the Rotary VPC™ (vacuum pre-classifier) screens heavy debris before the grit is dried, and a powerful fan/dust collector constantly collects the dust. The cleaning process works as the grit moves through the drum, removing substantial dust before it reaches your recycler, where it will be cleaned/recycled even more effectively because it is dry.

Yes. Try the Rain Day Cost Calculator™ to analyze your projects with as many "What-If" scenarios as you would like to see. It could save you 20-30 or more days per year, giving you roughly an entire month of “found time and found money”.

We estimate fuel consumption to be about 10-15 gallons per hour if you have let the running water drain away first. With less water to be removed, less heat and diesel fuel are required.

Yes . . . we will train your people on your job site using our SURFACE Training Rig before you connect up to the dryer you have rented and vacuum grit in production. This will take 1-3 days which include classroom and hands-on operation training of the GD1K-T ROTO Grit Dryer™ while actually vacuuming wet steel grit.

Although we do not have authority to provide any industry certification for operators, we will provide personalized certificates upon the successful completion of our training. We realize that for you to maintain the safest and most efficient operations, operator training must be updated as machines are periodically revised and/or you change personnel. If you have an in-house training program, we will gladly "train your trainers".

CONTACT

NEED HELP? CALL US!

877.446.7386

For Rental Sales and All Other Inquiries:

info@surfaceworldwide.com